-

Property & Casualty

Property & Casualty Overview

Property & Casualty

We offer a full range of reinsurance products and the expertise of our talented reinsurance team.

Expertise

Publication

Structured Settlements – What They Are and Why They Matter

Publication

PFAS Awareness and Concern Continues to Grow. Will the Litigation it Generates Do Likewise?

Publication

“Weather” or Not to Use a Forensic Meteorologist in the Claims Process – It’s Not as Expensive as You Think

Publication

Phthalates – Why Now and Should We Be Worried?

Publication

The Hidden Costs of Convenience – The Impact of Food Delivery Apps on Auto Accidents

Publication

That’s a Robotaxi in Your Rear-View Mirror – What Does This Mean for Insurers? -

Life & Health

Life & Health Overview

Life & Health

We offer a full range of reinsurance products and the expertise of our talented reinsurance team.

Publication

Key Takeaways From Our U.S. Claims Fraud Survey

Publication

Favorite Findings – Behavioral Economics and Insurance

Publication

Individual Life Accelerated Underwriting – Highlights of 2024 U.S. Survey

Publication

Can a Low-Price Strategy be Successful in Today’s Competitive Medicare Supplement Market? U.S. Industry Events

U.S. Industry Events

Publication

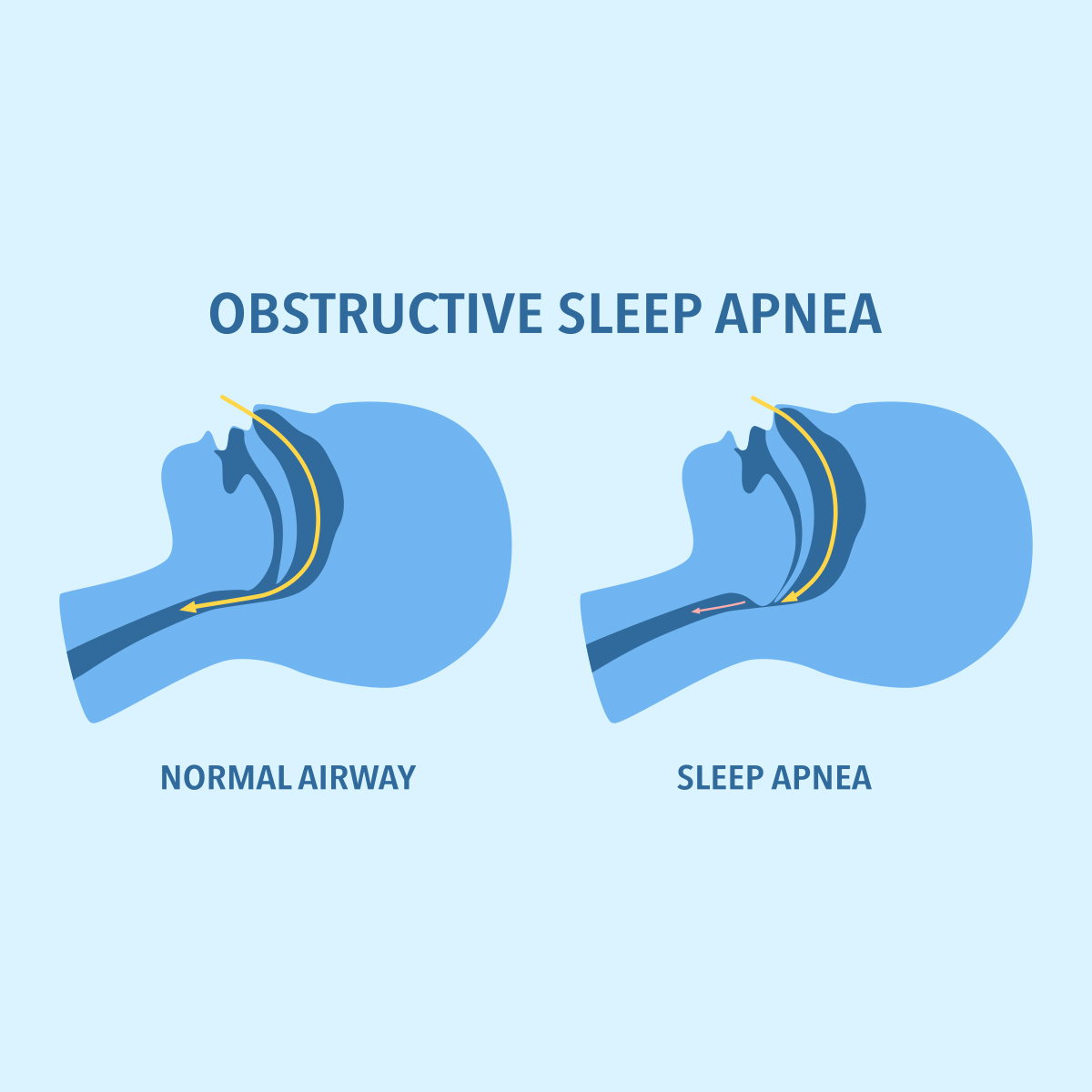

The Latest in Obstructive Sleep Apnea -

Knowledge Center

Knowledge Center Overview

Knowledge Center

Our global experts share their insights on insurance industry topics.

Trending Topics -

About Us

About Us OverviewCorporate Information

Meet Gen Re

Gen Re delivers reinsurance solutions to the Life & Health and Property & Casualty insurance industries.

- Careers Careers

Production of Lithium-Ion Batteries

April 24, 2024

Leo Ronken

English

Deutsch

The transition away from fossil fuels towards CO2‑neutral energy is leading to an increasing demand for batteries/accumulators. Lithium-ion batteries (Li‑ion batteries or LIBs) are regarded as suitable for meeting this demand. Consequently, considerable investments are being made in new manufacturing plants and in research to further improve the technology. The technology is still relatively new, and there is limited experience of the risks and damage associated with its manufacture. What is known is that lithium-ion batteries pose a challenge for firefighters in the event of a fire, as has already been demonstrated by several incidents.1 What is also known is that this rapidly expanding technology presents underwriting challenges.

This article outlines a typical manufacturing process by way of example, highlights potential sources of risk from a Property Insurance perspective, and provides advice on fire protection measures. The article concludes with tips for property underwriting. It should be noted that both the manufacturing processes – and therefore the risk situation – and the resulting fire protection measures vary, so the examples provided should be taken only as a guide.

Types of Lithium-Ion Batteries

There are various types of lithium-ion batteries, each of which differs in terms of materials used for the electrodes and the electrolyte, and the design (see table for examples):

|

Types |

Anode |

Cathode |

Advantages |

Disadvantages |

Applications |

|---|---|---|---|---|---|

Lithium iron phosphate batteries (LiFePO4) |

Graphite |

Lithium iron phosphate (LiFePO4) |

long service life, good thermal stability, high discharge rate, low risk of thermal runaway |

|

e.g., electric vehicles, renewable energy storage, emergency power supply |

Lithium cobalt oxide batteries (LiCoO2) |

Graphite |

Lithium cobalt oxide (LiCoO2) |

high specific energy density, good discharge performance |

shorter service life compared to other types, sensitive to overcharging and high temperatures |

e.g., electronic devices, laptops, smartphones |

Lithium manganese oxide batteries (LiMn2O4 or LMO) |

Graphite |

Lithium manganese oxide (LiMn2O4) |

high discharge capacity, good thermal stability |

lower specific energy density compared to other types |

e.g., power tools, medical devices, electric bicycles |

Lithium nickel manganese cobalt oxide batteries (NMC) |

Graphite |

Mixture of lithium nickel cobalt manganese oxide (LiNiCoMnO2) |

good balance between specific energy density and discharge capacity, improved service life compared to pure LiCoO2 batteries |

|

e.g., electric vehicles, energy storage solutions, power tools |

Lithium iron manganese phosphate batteries (LiFeMnPO4) |

Graphite |

Mixture of lithium iron manganese phosphate (LiFeMnPO4) |

good service life, high discharge capacity, good thermal stability |

|

e.g., electric vehicles, renewable energy storage solutions |

Lithium titanate batteries (LTO) |

Lithium titanate (Li4Ti5O12) |

Lithium iron phosphate (LiFePO4) or lithium nickel cobalt manganese oxide (NMC) |

high charging and discharging capacity, very long service life, high level of safety, good performance at extreme temperatures |

|

e.g., electric vehicles, energy storage solutions, fast charging systems |

Choosing the right battery depends on the requirements of the application. Considerations include energy density needs, discharge capacity, service life, and safety. As LIB technology development continues, the variety of battery types will continue to increase.

Exemplary Manufacturing Process

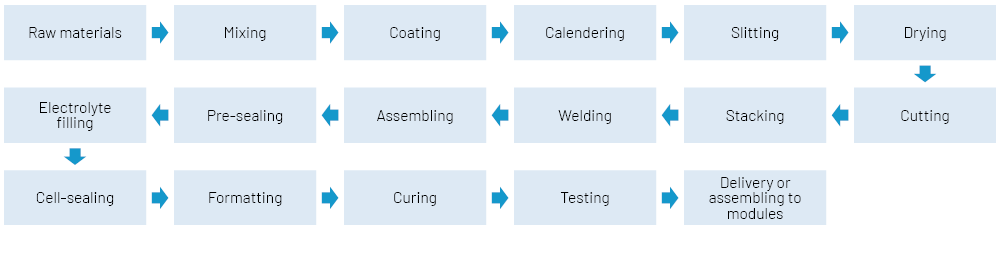

The production of lithium-ion battery cells is a complex process.2 It can be summarised as follows:

- Material sourcing

The basic materials for lithium-ion batteries include lithium (as lithium cobalt oxide, lithium iron phosphate, or other compounds), electrode materials (such as graphite for the anode and metal oxides for the cathode), electrolyte (usually a lithium salt solution in an organic solvent), and separator material (usually a porous polymer). - Production of the electrodes

The electrodes are produced from active material, a conductive agent, and a binder, which are combined by mixing and dispersing the substances with the addition of a solvent (so‑called slurry). They are mixed in a continuous process to form a uniform paste. The mixture differs depending on whether it is to be used for cathode or anode production. The paste is then temporarily stored or transported directly via pipelines to the coating system, where it is applied simultaneously to both sides of a metallic carrier foil (e.g., copper or aluminum foil) using an application tool (e.g., slot die, doctor blade, or anilox roller). The solvent or water still contained in the coating material is evaporated in the downstream drying system (thermal oil heated or infrared or laser drying). The highly flammable solvent contained in the cathode coating is either recovered or sent for thermal recycling.

The coated film strips obtained in this way form the starting material for the anode or cathode of the future cells. After drying, the films are cooled down to room temperature and, depending on the type of system, rewound (conventional) or, if they are initially only coated on one side, fed directly back into the coating system (tandem coating).

The electrode foils are then cut into rolls. The process is followed by a calendering process in which the film coated on both sides is compacted by a rotating pair of rollers (top and bottom rollers) after it has first been statically discharged and cleaned. This gives the electrodes the required thickness and, through a defined line pressure, the desired porosity, which determines the subsequent wetting behavior of the electrodes and the energy density of the cell.

This is followed by the actual electrode production (so‑called slittering). The dried, rolled‑up strips are divided into smaller electrode strips of the desired width. As a rule, rolling knives or lasers are used for this. After the cutting process, the individual smaller coils are cleaned and rolled up again and dried in a vacuum oven for 12 to 30 hours. This removes residual moisture and solvents from the coils. The coils are then vacuum-packed. The respective electrode coils for the cathode or anode are then cut to the desired dimensions and separator sheets for cell assembly in a continuous process, usually using a punching tool or laser. - Production of the separator

The separator is made of porous polymer films that separate the electrodes and allow the electrolytes to flow between them while preventing direct contact of the electrodes. They are produced in rolls and later placed between the electrodes. - Assembling the cell (assembly)

First, the anode, cathode, and separator sheets are separated from the roll material (so‑called separation). The electrode strips obtained (anode and cathode) are stacked in a repetitive cycle of anode, separator, cathode, separator, etc. There are various industry-specific stacking technologies for this. The resulting cell stack is then fixed in place with adhesive tape.

Using an ultrasonic or laser welding process, the arrester foils (copper anode and aluminum cathode) of the stack are connected to the contact terminal before (e.g., for round battery cells) the stack is placed in a so‑called pouch cell (deep-drawn foil). The pouch cell is then initially sealed gas-tight on three sides; one side of the cell remains open so that the electrolyte liquid can be filled in under vacuum conditions in the next process step. This activates the capillary effect in the cell (so‑called wetting). Vacuum evacuation and partial filling are repeated several times, depending on the manufacturer and cell type. Finally, the pouch foil is sealed under vacuum.

The electrolyte filling stage is sometimes followed by an optional pressing process to optimize the distribution and absorption of the electrolyte through the associated pressure, thus avoiding electrochemically inactive areas. - Formatting of the cell

Forming refers to the initial charging and discharging processes of the battery cell according to precisely defined current and voltage curves to stabilize the electrochemical reactions within the battery and ensure that it reaches the specified capacities. During formation, lithium ions are deposited in the crystal structure of the graphite on the anode side. This forms the solid electrolyte interface (SEI), which is a boundary layer between the electrolyte and the electrode. - Maturation

Maturation is the final step in cell production and is used for quality assurance. During maturation, the cell properties and cell performance are monitored by regularly measuring the open-circuit voltage of the cell over a defined period of up to several weeks. The cells are stored in so‑called maturing racks and/or towers. A distinction is made between high temperature (HT) and normal temperature (NT) maturation. If there is no significant change in the cell properties during this ripening period, the cell is okay. - Quality control and tests

Before delivery, the battery cell is subjected to various quality, performance, and safety tests (e.g., measurement of internal resistance, visual inspection, leak test) to ensure that it meets the required reliability and longevity standards. It is then discharged to the shipping state of charge in preparation for delivery.

The individual battery cells can then be combined into modules to create lithium-ion batteries with greater capacity and energy density. Such modules can contain hundreds or thousands of individual battery cells.

Dangers During Production

The manufacture of lithium-ion batteries involves various hazards resulting from the materials used and the production process.

Chemical hazards

Lithium: Lithium is a reactive metal and may cause hazardous reactions on contact with water or air.

Electrolytes: The electrolytes used in lithium-ion batteries are often corrosive and can cause skin and eye irritation. They have a low flash point and can therefore form an explosive atmosphere.

Solvents: The organic solvents used in cathode production can be highly flammable and develop vapors that can be harmful to health and form an explosive mixture.

Carbon and graphite powders: These powders can lead to an explosive dust-air mixture, for example during mixing processes.

Process hazards

Mixing systems: This part of the manufacturing process may lead to the formation of an explosive atmosphere due to the solvents used or an explosive dust-air mixture. Furthermore, metal dusts in contact with water can lead to fires.

Drying ovens: Excess temperature in the drying ovens, for example, can lead to an increase in pressure and the creation of an explosive atmosphere.

Coating plant: This stage of the process may result in the formation of an explosive atmosphere or incipient fire.

Calendering system: The calendering rollers are often heated with thermal oil; leaks can lead to fires.

Electrolyte filling: The electrolyte liquid has a low flash point; there is a risk of fire or explosion due to the formation of an explosive atmosphere. Hydrogen fluoride (a highly toxic gas) can be produced on contact with water, for example in the event of leaks in the electrolyte-carrying pipes.

Extraction and filter systems: Extraction of solvent vapors or metal/graphite dust poses a risk of explosion and fire.

Formatting process: There is a fire hazard primarily due to thermal runaway of a cell in the event of an internal fault or contamination (thermal runaway).

Maturing process: At this stage there is a risk of thermal runaway of a cell.

Quality and testing process: At this stage there is a risk of fire due to a thermal runaway of a cell caused by the failure of a cell.

In general, it should be noted that lithium-ion batteries can overheat and catch fire or even explode after formatting and during the subsequent process steps in the event of improper handling, storage, damage, or overcharging. In addition, there are electrical hazards due to the charging and discharging processes of the battery cells.3

Storage hazards

Storage of raw materials: Some of the raw materials used are flammable liquids or combustible dusts. Their uncontrolled release can cause a fire or explosion hazard.

Storage of finished goods: There is a risk of thermal runaway due to contamination, overcharging or undercharging, damage, improper handling of the battery cells, and improper storage conditions.4

Fire Protection Measures in the Manufacture of Lithium-Ion Batteries

In addition to the usual preventive measures that apply to all operating modes, the manufacture of lithium-ion batteries requires special fire protection measures, particularly in areas where a thermal runaway event is possible. Special attention must, therefore, be paid to all areas from the moment the battery cell is charged.

To date, there are no coherent guidelines, rules, or regulations for the necessary protective measures in the manufacture of lithium-ion batteries. There are isolated references in NFPA, VdS, and FM Global guidelines/data sheets for some areas in which lithium-ion batteries are handled,5 but these do not cover all areas of production. There are also internal manufacturer safety instructions and rules, but these are not publicly accessible.

The list below outlines various fire and explosion protection measures, but may not cover all possibilities.

Structural fire protection measures

Structural fire protection measures are the backbone of preventive measures to avoid fire/explosion damage or at least to reduce the resulting consequences.

- Wherever possible, combustible building materials and components should not be used in the construction of buildings. This applies particularly to avoiding the use of combustible insulating materials for walls, ceilings, and roofs. It is advisable to construct the building using fire-resistant construction methods to prevent rapid collapse of the building structure in the event of a fire. In areas where there is a risk of explosion, the build‑up of dangerous explosion pressures in the building should be prevented by structural measures (e.g., pressure relief openings).

- If possible, the individual production sections should be separated into discrete complexes (e.g., spatial or structural complex separation) or, as a minimum, by fire walls that extend at least 50 cm or 1 m beyond the roof covering through all storeys without being offset in order to contain a possible fire to the affected fire section if necessary.

- All openings and penetrations through fire-resistant walls and ceilings should be at least fireproofed to prevent a fire from spreading to the neighboring section.

- Tank systems for the storage of flammable liquids should, if possible, be housed in a separate and fire-protected building or be located underground. If it is not possible to store smaller containers in a separate building, a separate fire-resistant room should be set up for the storage of smaller containers.

- The ripening warehouse and the finished goods warehouse should both be physically separated from the production building. The spatial distance should be dimensioned in such a way that in the event of a fire, for example one triggered by a thermal runaway, the fire is prevented from spreading to the production building. Separation by fire walls is not sufficient to safely prevent the spread of fire due to the special combustion characteristics of lithium-ion batteries.6 It is also expected that fighting a fire in a burning lithium-ion battery storage facility will pose major challenges for the fire department and will require several days of firefighting.

- It is expected that photovoltaic systems will be installed on buildings for the production and storage of lithium-ion batteries to prevent the possibility of an incipient fire starting from an installed photovoltaic system. To limit the consequences of a fire, they should be installed only on roofs with non-combustible roofing or on façades made of non-combustible building materials/components where possible.

Technical/operational fire protection measures

The systems used to manufacture the battery cells should comply with the rules of technology and have the necessary technical safety measures in place. These include, for example, temperature/pressure and other measuring sensors and automatic shutdown and emergency stop devices as well as ventilation and flushing equipment. Pipes in which flammable liquids are transported should be double-walled to prevent leaks. The use of thermal oil systems for heating systems should be avoided wherever possible. Measuring sensors and safety devices should be coupled with an automatic alarm messaging system that sends information to a control room staffed around the clock.

In addition, the following measures should be considered from a fire and explosion protection point of view:

- Equipping all operating areas with an automatic stationary fire alarm system with alarm forwarding to a location (e.g., fire department) at all times that can detect an incipient fire as quickly as possible and initiate extinguishing measures. Care should be taken to ensure that the fire alarm system is planned and installed by a certified specialist company in accordance with the rules of technology (e.g., VdS guideline 2543)7. Appropriate gas detectors should be installed in potentially explosive areas.

- Enough suitable fire extinguishers should be kept in strategic points throughout the production facility, determined by the fire hazards in each area of operation, so that any incipient fire can be extinguished immediately.

- To combat an incipient fire, it is advisable to equip the entire business with an automatic sprinkler system or another effective fire extinguishing system. The system should be planned and installed by a certified specialist company in accordance with the relevant VdS9 or FM Global9 guidelines. It is recommended that the insurer be involved in advance of the planning stage and agree to the planned preventive measures. After installation, the system should be inspected by an accredited inspection body, e.g., a VdS or FM Global technical inspection body, in order to guarantee that the installation is free of defects. Any defects found should be rectified immediately so as not to jeopardize the extinguishing effectiveness of the system. Where metal powders/dusts are handled, appropriate special extinguishing agents should be kept in stock: they should possibly be excluded from sprinkler protection, as many metal powders react with water to form water and oxygen, causing additional fire and explosion hazards. Experience has shown that special extinguishing systems are suitable for such areas, e.g., powder extinguishing systems with metal fire powder or inert gas extinguishing systems. The electrolyte filling area/system should also be protected with an inert gas extinguishing system. There is a particularly high risk of fire during the formatting process, so this area should be comprehensively protected with an automatic sprinkler system and form its own fire-resistant separated area.

- In addition to the recommendation that the maturing and finished goods warehouse be housed in buildings separate from the production building, the storage areas should have an adequately designed sprinkler system in accordance with the requirements of the relevant VdS guidelines and FM Global data sheets. In the event of an incipient fire, the sprinkler system may be able to cool the fire area and support the fire department in their operations. In the racks, the rack storage areas should be divided into smaller storage compartments by the arrangement of vertical and horizontal steel sheets to prevent a fire from spreading quickly to the neighboring storage compartments. The individual storage compartments should be equipped with rack sprinklers. Block storage should be avoided. Defective or damaged cells and modules should be stored outside the storage building in a separate building.

Organizational fire protection measures

- Employees should be trained when they are hired and at least once each year on the specific hazards involved in the manufacture of lithium-ion batteries, the correct behavior in the event of a fire, and the safe handling of lithium-ion batteries.

- Companies should develop a detailed emergency plan with clear instructions for evacuation procedures and how to deal with batteries in the event of a fire. In addition, a fire department plan should be prepared to inform the fire department quickly and clearly about the expected hazards, existing structural and technical fire protection measures, and available extinguishing measures in the event of an alarm. The fire department plan should include the following:

- Possible fire department bypass options and marking of the set‑up areas for the fire department

- Existing extinguishing water extraction options

- Safe storage options for damaged lithium-ion batteries or those involved in a fire

- Special hazard areas such as storage areas with flammable liquids and potentially explosive areas.

- Other preventive organizational measures include tidiness and cleanliness, regular maintenance and servicing of all systems, immediate rectification of all defects identified, regular inspection, and maintenance of all electrical systems.

Storage and handling

- Particular attention should be paid to storage areas, notably to the safety regulations for the storage, handling, and disposal of lithium-ion batteries. Areas that pose a particular hazard should be marked accordingly.

- The necessary storage conditions for lithium-ion batteries should be observed. This applies in particular to the storage temperatures and to the handling of the batteries.

- There should be no mixed storage. Other stored goods should be kept in a separate building or in a separate fire compartment.

- Only new batteries should be stored in the warehouse. Returned or damaged batteries should be stored in a separate room or in specially designed and approved transport or storage containers and sent for recycling as quickly as possible.

- The individual shelving systems for lithium-ion batteries should be divided into smaller storage compartments by horizontal and vertical sheet metal barriers.

- The storage heights in rack storage systems for lithium-ion batteries should be limited.

- The battery storage facility should be fully protected by an effective and optimized sprinkler/water spray fire suppression system in accordance with the relevant VdS and FM Global guidelines.

- The warehouse should be equipped with smoke aspiration fire detection technology as well as gas detectors (i.e., detection of particles in an electrolyte gas) and thermographic detection systems to monitor the warehouse temperature and to raise the alarm as early as possible in the event of a fire.

- For the existing storage buildings, a sufficient supply of extinguishing water must be available to enable cooling and firefighting for several days.

- The battery storage facility should also have an extinguishing water retention system to safely collect the contaminated extinguishing water produced during cooling and firefighting and to prevent it from flowing uncontrolled into the environment.

- Further information on the safe storage of lithium-ion batteries can be found in FM Global Data Sheet 8‑1 Commodity Classification (2.4.2 Lithium Ion (Li‑Ion) Batteries)11 as well as in VdS leaflets 3103 Lithium Batteries12 and 3856 Sprinkler Protection of Lithium Batteries.13

Defensive fire protection

- To ensure good and safe accessibility for firefighters in the event of a fire, all existing buildings should have a fire department bypass as well as sufficient and safe parking areas for equipment and vehicles.

- Determined in consultation with the fire department, a sufficient supply of extinguishing water should be provided. Extinguishing water extraction points should be clearly marked and safely accessible to firefighters.

- The fire department should be familiar with the location and the company before a fire breaks out. It is advisable to invite the relevant fire department to conduct a drill on company premises to familiarize themselves with the site’s specific risk situations. The exercise should be repeated regularly, possibly annually.

Explosion measures

In addition to the risk of fire, lithium-ion battery facilities face a latent risk of explosion during production caused by solvents or graphite/metal powder, for example. To limit the possible effects of or even avoid an explosion hazard, the relevant primary, secondary, and tertiary explosion protection measures should be observed and implemented where necessary. Corresponding measures (e.g., pressure relief, explosion suppression, explosion-proof electrical systems) are described in the explosion protection rules of the DGUV14 and FM Global data sheets 7‑0 and 7‑17.15

Notes for Underwriting

The production of lithium-ion batteries is a relatively new technology, making it particularly challenging for Property Insurance underwriting. That there are few regulatory or legal requirements further complicates the underwriting process. As a result, the industry does not yet have clear instructions or established best practices. However, in addition to general underwriting recommendations, there are a number of Property Insurance risk assessment tips that may be relevant to a lithium-ion battery manufacturer’s risk assessment.

Structural situation

- Were the buildings constructed with non-combustible building materials and components? Particular attention should be paid to the insulation of the walls and roofs.

- Is a photovoltaic system installed on or near the building? If yes, was it installed by a specialist company and approved by an expert?

- Are the production buildings separated from the maturing and finished goods warehouse according to fire protection protocols so that the probability of fire spreading to other buildings in the event of a major fire is reduced?

- Are the individual process sections where lithium-ion batteries are manufactured, in which flammable substances are handled and in which the cells are charged for the first time, separated by fire walls that extend at least 50 cm above the roof of the higher building without being offset through all storeys, and are their openings protected against fire?

Operating process

- What are the company’s operating hours? Are there operational shutdown periods?

- Are cleanrooms present in the operating process and what is their classification? For example, electrode production takes place under cleanroom conditions since foreign particles in the coating can no longer be removed by cleaning methods (e.g., vacuuming) later in the process. Even an incipient fire can lead to considerable consequential damage if cleanroom conditions are compromised.

- Is cell assembly carried out under dry conditions? Water inside the cell has multiple damaging consequences, among them a severe loss of quality (i.e., service life) and a safety risk due to the formation of hydrofluoric acid.

- Are thermal oil systems present in the company? Is the heating source located in a separate fire-resistant room and are the necessary pipes double-walled? What temperature is the thermal oil heated to, and what is the flash point of the thermal oil used?

- How and where are flammable substances including gases, metal powder, and flammable liquids stored and what preventive fire protection measures have been taken?

- Are returned or damaged battery cells stored outside the finished goods warehouse in a separate fire-resistant protected room or in a special transport/storage box approved for this purpose?

- How is maintenance and servicing carried out? Is there a schedule of programmed maintenance and are any detected defects rectified immediately?

Special fire protection measures

- What structural measures are in place to prevent the fire from spreading uncontrollably in the event of an incipient fire?

- Is the company equipped with an automatic fire alarm system throughout? Is there an alarm forwarding system connected to a location staffed around the clock? According to which rules/guidelines was the system planned and installed and is an installation certificate available? What type of fire detection technology was used? Smoke aspiration technology has proven particularly effective. Have gas detectors also been installed where necessary?

- Is the business equipped with a stationary automatic fire-fighting system (e.g., sprinkler/water spray extinguishing system) throughout? According to which regulations was the respective system planned and installed? Is there an installation test and are the systems regularly (e.g., annually) inspected by an expert? Are corresponding inspection certificates available? Have any found defects been rectified?

- Are appropriate compensatory measures (e.g., gas extinguishing systems) installed in areas where a sprinkler/water spray extinguishing system would be counterproductive?

- Which fire department is responsible for the company and do they have appropriate local knowledge (e.g., drills on site, company inspections)?

- Are there fire department bypasses around the buildings and sufficiently safe areas for the fire department’s equipment and vehicles?

- How is the extinguishing water supply secured and what quantities are available? Particularly in the event of a fire caused by a thermal runaway, it is likely that cooling and firefighting will be necessary for days, if not weeks.

- Are there extinguishing water collection facilities? It is to be expected that uncontrolled discharge of the extinguishing or cooling water will result in contamination of the surrounding area.

- Is there regular training/instruction on the specific hazards involved in manufacturing and storing lithium-ion batteries and the handling of charged batteries in particular?

- Does the company have a business continuity plan and is it regularly updated and tested as part of an emergency drill?

Underwriting issues

- What wording is the insurance contract based on (e.g., standard wording or manuscript wording) and what is the scope of insurance (e.g., named perils, all-risk or partial cover, machinery breakdown, additional cost agreements, agreed additional cover)?

- Is there a breakdown of the sum insured between buildings, equipment, inventories, and business interruption? Ideally, the sum insured should be divided between the individual buildings as this makes it easier to estimate the maximum loss.

- What insurance values are attributable to the storage areas (e.g., annual average value, maximum peak value) and what is the inventory turnover rate?

- What is the compensation basis of the stored goods (e.g., sales price, wholesale price, manufacturing cost, fixed price/agreed price, including or excluding taxes)?

- Are repercussions/interactions insured in accordance with the insurance contract, and what are the insured liability amounts? What other first-party risk items are insured in the insurance contract (e.g., decontamination costs, fire extinguishing costs, clean‑up costs, provision sums, additional costs) and how high are these?

- Is there an underinsurance provision?

- What is the duration of the liability period for the business interruption insurance, and is it adequate to cover the business interruption exposure?

- What deductibles and any maximum compensation have been agreed?

Insurance exposure

- Is a current technical survey report available that covers all necessary aspects for underwriting and the underwriting decision?

- Is the maximum loss definition/scenario used by the surveyor/broker/insurer known? Has a realistic maximum possible loss (MFL) been determined by the surveyor/risk engineer, broken down into property and business interruption, costs, and wages?

- Are there any accumulations from other existing insurance contracts (e.g., liability, environmental liability, electronics, machinery breakdown policies, from underwritten insurance contracts for surrounding risks)?

- What is the claims history, what type of damage has occurred, and what compensation amounts have been paid?

- What replacement times for buildings and/or systems and what business interruption times would have to be expected after a fire (e.g., total loss of a building, total loss of an essential system)? Are special operating licences required for the operating process? What “bottlenecks” are present in the operation and what possible alternatives/replacement options exist?

- What is the natural hazard exposure (e.g., flooding, earthquake, storm, forest fire)?

Conclusion

Lithium-ion battery manufacture, storage, and use present new and evolving underwriting challenges for property insurers. As battery/accumulator technology continues to develop, additional or different risks may arise. Insurers should monitor these developments closely and regularly review and adjust their underwriting accordingly.

Download PDF version for Further Reading and Endnotes.